The LZB/LZJ series glass rotor flowmeter is widely used in chemical, petroleum, light industry, medicine, environmental protection, food and metrology testing, scientific research and other departments to measure the flow rate of single-phase non pulsating fluids (liquids or gases).

The LZB/() F/LZJ - () F series corrosion-resistant glass rotor flowmeter has strong corrosion resistance and can detect the flow rate of acids (except hydrofluoric acid), alkalis, oxidants, and other corrosive gases or liquids. It is suitable for industries such as chemical, pharmaceutical, papermaking, and sewage treatment.

| Appearance and installation dimensions | |

|

|

|

principle and structure

|

|

|

The cone tube of LZB/LZB - () F flowmeter is a smooth inner wall tube (see Figure 4). For flowmeters with a diameter of DN15 or more, the float moves up and down through the guide rod to maintain stability; There are three guiding ribs on the inner wall of the cone tube of LZJ/LZJ - () F flowmeter, which keep the float stable (see Figure 4). Flow meters with a diameter of DN10 or less are connected by hoses and equipped with needle shaped flow control valves; Flow meters with a diameter of DN15 or above shall be connected with flanges.

|

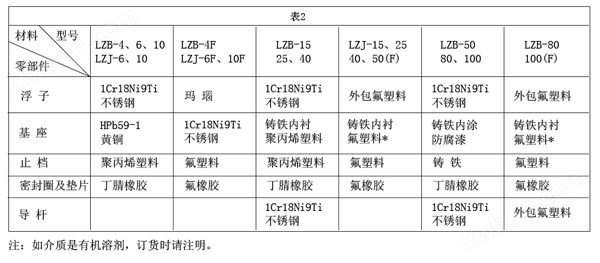

Materials of components in contact with measuring fluids |

Model specifications and technical parameters

All stainless steel type

The flange, float, guide rod, support plate, and bolts are all made of stainless steel 304 (1Cr18Ni9Ti), with the model LZB - () B.

If 316 is required for the liquid receiving material, the model is LZB - () Bo and it needs to be customized.

If stainless steel lined with PTFE is required, the model is LZB - () BF (or BoF), which needs to be customized.

Full tetrafluoroethylene type

|

The base, float, and needle valve are made of polytetrafluoroethylene (PTFE). Support plates, screws, etc. are made of stainless steel

|